Nygaia x automation

We understand you’re ambitious, and want to produce as sustainably and efficiently as possible while maintaining maximum control. Preferably on a large scale, but with a minimal negative impact on people and the environment. That’s quite a challenge, so take a step in the right direction right now!

Technology is the solution

The horticultural industry is facing a number of challenges in the sustainability transition. Nygaia facilitates sustainable cultivation, but what about the substrate itself? Many substrates are made from non-renewable raw materials which require considerable CO2 emissions or energy to be extracted. On top of this, containers are shipped all over the planet in order to keep growers supplied, which nobody could call a sustainable system. For these reasons, we looked for an integrated approach when we developed Nygaia. An all-encompassing concept which combines biodegradable and at least partly renewable substrate with the automation needed to produce it as locally as possible (on site). Good news for you, and great news for the planet!

Revolutionary: the Nygaia Plugline

Our engineers developed the Nygaia Plugline. Which enables you, as a grower, to produce your own substrate on site; always fresh, and completely adapted to what you need at that moment. This gives you complete control over your own substrate, reduces your dependence on deliveries, and brings an end to overproduction. We supply the raw materials (this reduces the number of transport movements by a factor of up to 40) and the automation, you do the rest.

How does it work in practice?

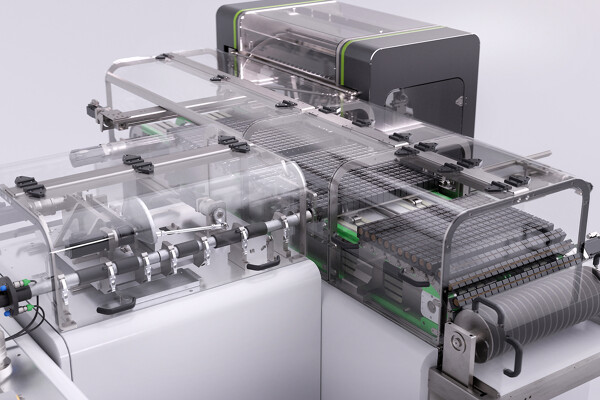

The Nygaia Plugline consists of three modules. First of these is the Nygaia Printer, which produces fibre from granules. As the name suggests, the fibre is ‘printed’, resulting in a fibre mat; which is sent to the second module; the Nygaia Converter. (The Nygaia Printer is currently under development)

The Nygaia Converter rolls the fibre mat into a long, airy, string of fibre. That might sound simple, but it relies on a special patented roll-up mechanism to ensure the structure is consistently uniform and stable. The diameter is continuously monitored, and the density or size are easy to adjust to suit your needs.

The second stage in the conversion process is the cutting station, where the strand is cut to the correct plug size. These plugs are then transported to the Nygaia Trayfiller, which places the plugs one row at a time in a tray, ready for use!

The Nygaia Plugline can be integrated into a new or existing automatic planting line.

How you benefit as a grower:

+ Maximum control

+ No overproduction

+ Easy to use and clean

+ Safe

+ Energy-efficient

+ Little surface area required

Are you ready to take horticulture into a new era?

Are you an early adaptor? Do you want to lead the pack and join us in our belief in a world where healthy, fresh products are available to everyone, everywhere? Then take up the challenge with us.

The developers

Klasmann-Deilmann

Leading the market by delivering what’s needed today and developing what’s needed tomorrow. We’re resolutely building on our lead by drawing on over a century of expertise in commercial horticulture, constantly looking for renewable sources, ground-breaking substrate mixtures, and innovative solutions. Due to our worldwide presence, we can soon make Nygaia available to any forward-thinking grower, anywhere in the world.

Maan Biobased Products

We look further where others give up, convinced that the better solution is waiting to be found. We are discoverers. Strengthened by our vast expertise in biobased and biodegradable materials, we foster cross-over innovations from prototype to process, to end product and production. The horticultural sector holds a special place in our hearts. Research & development today, to produce Nygaia tomorrow. We’re ready.